How To Fit A Bifolding Door – A Step by Step Guide

Share this story!

Share this post to any popular social media, email it to a friend or print it off.

Index

• Introduction

• How Long Does It Take?

• Tools and Supplies

• Basic Operation of a Bi Fold Door

• Installation Instructions

o Part 1 – Preparation of the Opening

o Part 2 – Handling of Components

o Part 3 – Installing the Outer Frame

o Part 4 – Installing the Sill

o Part 5 – Installing the Door Panels

o Part 6 – Final Fixing Screws

o Part 7 – Glazing

o Part 8 – Final Checks

• Toe & Heel Glazing Guide

• Frame Assembly from Kit Form

• Tips

• Video Guide

• Downloadable PDF Guide

Introduction

Bifolding doors are becoming more and more popular because of how they open up the indoors to the outdoors with their wide, unrestricted openings and slick smooth action. Aluminium bifolding doors are a genuine long-life product due to the robust profile, which has been designed to give strength and durability to ensure a structurally reliable performance over a lifetime of use. Before you start to fit your bifolding doors, you need to ensure you have the right planning permission to do so. Usually, the installation of bifolding doors would fall under permitted development, but it is best to double check.

If you’re looking to keep the cost down by fitting the bifolding door yourself, we’ve put together a step by step guide which may help you along the way. They may seem more complex to fit than, say, a patio door, but it is possible with enough time and patience. Bifolding doors are heavy, and you will need a helping hand to carry out the fitting. If you have no experience in window and door installation, you make want to ask a professional installer for help and advice. Before you start, it’s important to understand that bifolding doors rely on carefully balanced and sliding elements and most problems come down to poor installation. Quickslide will always recommend using a fully trained and FENSA registered installer to carry out the installation.

How Long Does It Take?

Typically, fitting a bifold door will take around half a day to a full day depending on the number of panels the door has. Installing a bifolding door into a new build property may take less time compared to a refurbishment project because no old silicone will need to be scraped off in order to create a clean, square and straight aperture.

Tools and Supplies Required

• Spirit Level

• Allan Keys

• Fixings (screws etc)

• Electric Drill

• Screw Drivers

• Scissors to cut out gasket for glass

• Foam Gun

• Silicone Gun

• Silicone

• Filler Knife

Basic Operation of a Folding-Sliding Door With Traffic Door

To Open

1. Unlock the traffic door and open it 180 degrees. This door will then close on to the next door via a magnetic panel catch (supplied in the parts box).

2. Unlock the remaining intermediate door panels using the intermediate handle (you do this by turning it nearly 180 degrees from pointing down (locked) to pointing up (unlocked).

3. Fold panels pair-by-pair sliding all of the panels carefully over to the side so they are all stacked together.

To Close

As described previously but in reverse order.

- Slide the pairs of intermediate door panels one-by-one back into the frame so they are shut.

- Lock each of these pairs off as you close them in to the frame.

- The traffic door should remain open and be the last door you close.

- Pull the traffic door closed and lift the handle upwards to engage the locking system in to the frame.so they are all stacked together.

Basic Operation of Folding-Sliding Door Without Traffic Door

To Open

- Unlock all internal handles.

- Slide the panels pair-by-pair slowly to the side so that they are all stacked together.

To Close

- Pull the handle between the panels closed so that you are working from the final set of opening panels to the first set of opening panels. Once these panels are pulled back tight against the frame, turn the handle to secure.

- Pull the second pair of panels closed and lock into the frame and turn the handle to secure.

Installation Instructions

IMPORTANT – Please ensure that the instructions are fully read and understood prior to fitting the bifolding door.

Regulations governing the use of glazed windows, doors, storefronts and/or partitions vary widely. It is the responsibility of the building owner, architect, contractor or installer to ensure that products selected conform to all applicable codes and regulations. Read our guide on building regulations for doors and windows for more information.

Quickslide can assume no obligation or responsibility whatsoever for the failure of the building owner, architect, contractor or installer to comply with all applicable laws and ordinances and safety and building codes with the exception of CE Marking.

Part 1 – Preparing the Opening

Make the aperture 15mm wider and 15mm higher than the outside frame size of the unit ordered.

Please note that the outside frame height of the required unit is measured from the underside of the sill and NOT FROM THE FINISHED FLOOR LEVEL.

IMPORTANT – Due to the large opening sizes, weight and movement of the panels, any application should take into consideration the following;

- The rough opening should be level, plumb and square at all points. There should be no unevenness or bowing. Make sure that the header is not twisted. There should be no bumps on the floor. The sides should be in the same vertical plane and not offset from each other. A telescopic rule and other similar precise measuring equipment should be used to make these determinations.

- The structural integrity of the header is critical for the proper operation. Deflection of the header should be limited to L/720th under full live and dead loads with a maximum deflection limit of 9mm.

- A qualified engineer or architect should be used to determine the proper construction details and header to be used in your particular application.

TO AVOID FUTURE PROBLEMS, DO NOT INSTALL THE UNIT UNTIL THE ROUGH OPENING HAS BEEN CORRECTLY PREPARED.

Part 2 – Handling of Components

1. Upon receipt of the products, please carry out a thorough inspection to ensure that all items have been delivered in good suitable condition.

2. Store the products in a secure, clean and dry environment and protect against defacement or damage.

3. Mark sure that the parts box supplied is not mislaid.

Parts & Ancillaries Checklist

External hinge plates: 1 per hinge (excluding wheels and guides)

Keys: At least 3

First fix screws: 2 per hinge (including wheels and guide)

Final fixing screws: 8 per glass unit

Toe and Heel glazing packers: 1 per traffic door

Magnetic panel catch: 1 per traffic door

Lifting block and screw (traffic door only): 1 per box

Toe and Heel diagram: 1 per box

2.5mm Allen key: 1 per box

3mm Allen key: 1 per box

Sill and caps (if applicable): Suitable quantity for all panels

Glazing gasket (attached to the door or sill)

Part 3 – Fitting the Outer Frame

Note: This part requires minimum 2 people

- Remove all door panels from outer frame making a note of each one’s location in the frame. 2 people should lift the outer frame in to the aperture and on to the sill.

- If there is no sill applicable to your order then please refer to the instructions below;

- Create a silicone bed on the masonry for the outer frame to sit on.

- Temporarily secure the frame to the rough opening with clamps.

- Make sure that the frame threshold is packed underneath to make it level and plumb (packers not supplied).

- Pre-drill all fixing points first then fix through the thermal break of the outer frame in to the masonry using suitable frame fixings (not supplied).

- Fix through the thermal break of the outer frame in to the sill at 100mm from each end and 600mm between.

- Before fixing the sides and head, the outer frame should again be packed suitably to ensure it is square and plumb.

- Fixing points should be set 100mm from each corner of the outer frame and then every 600mm between.

- Once the outer frame is fixed in place, it should be level, square and plumb, this should be checked at every 600mm in both width and height using a suitable measuring device.

Part 4 – Installing the Sill

- If the bifold has a projecting sill (150, 190 or 225mm) fill the ends with silicone before the end caps go on to prevent a potential leak.

- Fit the sill end caps to the sill using a suitable silicone (not supplied).

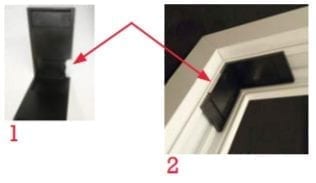

- Make a silicone bed on the masonry, sit the sill in to the aperture and pack underneath to make it level, then fix through the thermal break of the sill into the masonry. (Fig 1)

- If the thermal break of the sill sits over a cavity, then you are able to put a fixing through any point of the sill providing that it is covered by the outer frame. We would suggest that you use the thermal break as the first choice fixing point where possible.

- You must ensure that you apply additional silicone sealant to the ends of the sill where it meets the masonry as this will always be the most susceptible point for water ingress.

- When you are ready to sit the outer frame on to the installed sill, you should first run a line of silicone across the internal up-stand of the sill. (Fig 2)

Part 5 – Installing the Door Panels

- All loose door panels will carry a numerical label which stipulates the order in which they should be fitted in to the outer frame.

- Door ‘1’ will have hinges on one side only which will then connect to the outer frame using the ‘first fix’ screws and external hinge plates (3mm Allen key is included).

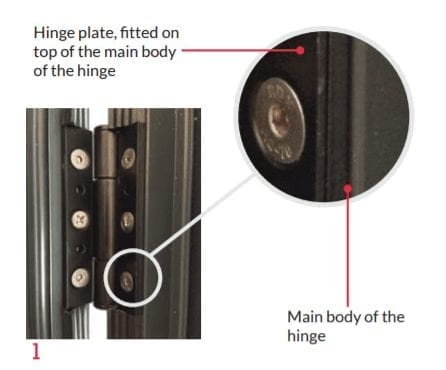

- The external hinge plates are first to be located on top of the hinge, as shown (Fig. 1)

- This should be repeated on the remaining hinges on door 1.

- Repeat the above steps fixing door 2 to door 1 etc…

Installing a Door Panel

- The sliding post will always be hinged to a door panel so this item does not require any additional construction.

- This type of door panel is hinged the same way as a standard panel but should be fitted in to the outer frame on an angle so that the guides are able to clear the outer frame and sit in to the rebated channels at the top and bottom of the outer frame.

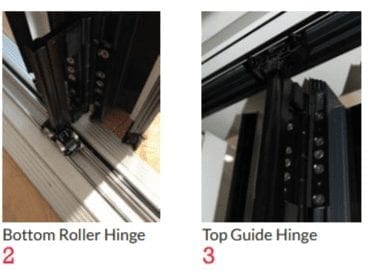

Installing a Door Panel with Wheels and Guides

- The wheels and guides will always be attached to the relevant door panel and are part of the top and bottom hinge assembly.

- These require hinges unlike the standard ones DO NOT require hinge plates to be fitted.

- This door panel should be fitted in to the outer frame on an angle so that the guides and wheels attached to the sliding post are able to clear the outer frame and sit in to the rebated channels at the top and bottom of the outer frame.

Part 6 – Final Fixing Screws

- Once all of the door panels have been fitted, you should ensure that all of the heads of the door panels ‘line-through’ with each other. (Fig 1)

- Assuming the panels do line-through then you can fit the ‘final fixing screws’ to the centre hole of ALL hinges including rollers and guides. (Fig 2)

The final fixing screws need to go in prior to glazing due to the weight of the glass.

Part 7 – Glazing

ALL GLAZING SHOULD BE CARRIED OUT BY A COMPETENT GLAZIER. GLAZING PACKERS AS WELL AS A TOE AND HEEL GUIDE HAVE BEEN INCLUDED.

- Remove the pre-glazed beading (4 per sash) keeping track of which bead goes where.

- Follow the toe and heel glazing guide for details on packer locations.

- Fit the bottom packers only prior to the glass units being installed.

- Lift the glass units into the door panel (2 people required).

- Fit remaining toe and heel wedge packers.

Part 8 – Final Checks

- After installation of the glass units, you should check the operation of the door to ensure that it is smooth with no catching door panels. If you find that a panel is catching you will need to adjust the toe and heel of the relevant glass unit.

- You should have an 11mm gap between the edge of the door panel and the edge of the outer frame (gasket line). This is applicable to all 4 sides of the outer frame. (Fig 4)

- You should ensure that all locking mechanisms operate correctly (traffic doors and intermediate doors).

- There should be no debris or residue in the bottom channel of the outer frame where the roller-bearing wheels are located.

Adjust Hinges

- The hinges can be adjusted up and down using the 2.5mm Allen key provided. This is done via a grub screw located on the internal of the hinge. In order for the adjustment to be effective, the final fixing screws will need to be removed and the first fix screws loosened.

- Toe and heel glass units for adjustment on the intermediate doors.

Toe & Heel Glazing Guide

Bifold door sashes are heavy, and although the dead weight is supported on the hinge side there is nothing on the lock side to support the weight. Toe and heeling of each sash is therefore essential to prevent the doors dropping and catching. This is especially a must for frames wider than 1000mm. We recommend following the steps below that explains how to use the device to reinforce the door, which essentially enables the glass to support its own weight. Please note not all doors come with a toe and heeler device and some doors may require conventional toe and heeling.

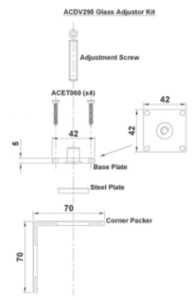

Toe and Heeler Device (ACDV295)

The Toe and Heeler device comes in 4 separate parts as shown to the right.

- a) Adjustment Screw

- b) Base Plate

- c) Steel Plate

- d) Corner Packer

The Base Plate and Adjustment Screw are pre fitted to the sash in the factory.

The Steel Plate and Corner Packer will come in the stores package and must be used in place of standard packers in the corners where the device is fitted.

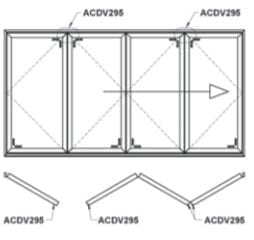

Where to Fit the Devices

To stop a door sash dropping it needs to be braced diagonally corner to corner by the Toe and Heeler devices between the glass and the frame. On the hinge side of the sash the devices go at the bottom corner, whilst on the lock side they go at the top (opposite corner).

Below is an example of where to fit the Toe and Heeler devices, you should use the same principle when glazing other configurations.

Fitting with a 28mm Glass Unit

The Toe and Heeler device will require a notch to be cut out when fitting 28mm units to allow the bead to sit in place, as shown below.

Please note: Failure to install all of the parts will invalidate the guarantee and could potentially shatter the glass unit.

Frame Assembly From Kit Form

If your frame was supplied in kit form, you are encouraged to carefully read the below instructions to correctly assemble the outer frame.

Step 1: Parts Box

If your bifolding doors have been supplied in kit form, you will receive a parts box which includes the following:

- 4 x silver tensions blocks per corner (total of 16 per panel)

- 1 x 2.5mm Allen Key

- 2 x final fixing screw per hinge

- 8 x packers per panels

- 4 x 50mm screws if you’ve opted for a low threshold

- Lifting block(s) if specified

Step 2: Remove Packaging

Remove the outer frame from its packaging and lay out the frame on a flat surface working area. The working area should be twice the height and width of the door.

The bottom of the frame will feature a drainage and steel track.

Step 3: Assemble Outer Frame

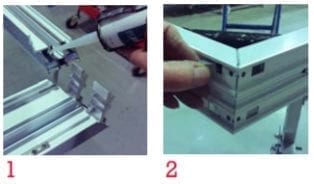

2 of the frame pieces will have 2 metal cleats (see illustration 1). Before assembling the pieces together, you will need to use silicone around the edges to weather seal the frame. The pieces should then be inserted into the channels. Once inserted place the silver tension blocks in the pre-punched holes.

Once the silver tension blocks have been inserted use the 2.5mm Allen key to tighten grub screws making sure surfaces are level.

Step 4: Gasket

The outer frame will come with a flipper gasket attached. This will need to be pushed into the groves all the way round the frame.

Tips

- You must toe and heel the glass into the openers; there will be a diagram in the fixing kit. This is a very important step! The glass panel in a bifold is obviously quite big and with that comes a lot of weight and to make sure the glass doesn’t drop each panel needs to be properly toe and heeled.

- Make sure Allan keys on the hinges on the doors are tight and use fixing screws provided to fix the hinges. You would be surprised how many people forget to fix the final fixing screws. When you think you’re done with the installation, go through each step again.

- Make sure on middle doors the key is taken out before opening and folding the doors to prevent it from snapping in the lock between two panes.

- Cut the gasket at an angle for it to fit nicely into the corners. We’ve introduced a new gasket that doesn’t need to be cut in each corner. The new gasket will only need to be cut once to fit around the glass section. Don’t leave the gasket too tight – it’s better to squeeze in a longer length because when you fit the gasket it’s hard not to stretch it but when it goes back to its normal form you want to make sure there are no gaps.

Watch the Video

If you follow these steps and tips carefully, you should be able to successfully fit your own bifolding doors. If you experience any issues whilst installing your bifolding door; it is best to get a professional installer to do it for you rather than risk damaging your home or the product. If you have any further questions, please get in touch via our contact form. Alternatively, give us a ring on 0333 241 2240.

- Bifold Doors vs. Slide and Stack Doors: Which Is Right for You? - 8 July 2024

- Quickslide Customer Days Heralded a Resounding Success - 21 June 2024

- Quickslide Presents the New Legacy On-screen Web Tool - 23 May 2024

Please note, our news articles are relevant and accurate at the time of release, but as technical developments dictate, and times goes by the information in this article may no longer be applicable. If you have questions, please contact us using our online contact form or call us on 03332 412 240.