Home of the Legacy Sash Window

Corner Joints

Standard Mitre Welded Sash

Our standard welding technique ensures that the corners are tightly bonded, creating a seamless and strong connection. The 45° corner welds are carefully cleaned using advanced machinery providing a clean frame finish.

Preview mechanically jointed outer frame and mitre welded sash.

Timber Looking Mechanical Joints

The fully mechanical joints take authenticity to another level because the 45° uPVC welds on the sash are replaced with 90° mechanical joints as found on traditional timber windows.

Run-through Sash Horns

By removing the lip on the sash horn edge, a new refined sash horn can carry a woodgrain foiled end cap that run seamlessly with the shape of the horn. The sash horn utilises mechanical joints rather than welded to allow the horn to be a continuous part of the sash giving the window a more authentic overall look. The new horn is available with the inclusion of a slim midrail only. On windows with a standard midrail, the run-through horn will look slightly different.

Preview sash horn design on windows with a standard midrail.

Tilt Knobs

Used to open and tilt the sashes for easy cleaning of the outside frame and glass from inside your home. The tilt knobs are available in two styles. Please view styles and finishes in the hardware section.

Astragal Bars

Include a bar layout on your new sash windows for added character. Astragal bars are fixed onto the surface of the glass and are accompanied by back-to-back spacer bars inside the double-glazed unit to give the appearance of separate panes.

Slim Midrail

The styling details of our sash windows are now more rooted in history than ever before. The new 37mm slim midrail will reaffirm the Legacy’s position as one of the most authentic sash windows on the market ideal for period properties or homes in conservation areas. Please note the slim midrail is available with the inclusion of run-through sash horns only and on windows with a minimum width of 375mm. Limitations on colourways may apply, please ask upon enquiry.

Sash Lock and Keep

Our locking system holds the sash window shut by fastening the mid-rails together. The locking system is available in two styles. Please view styles and finishes in the hardware section.

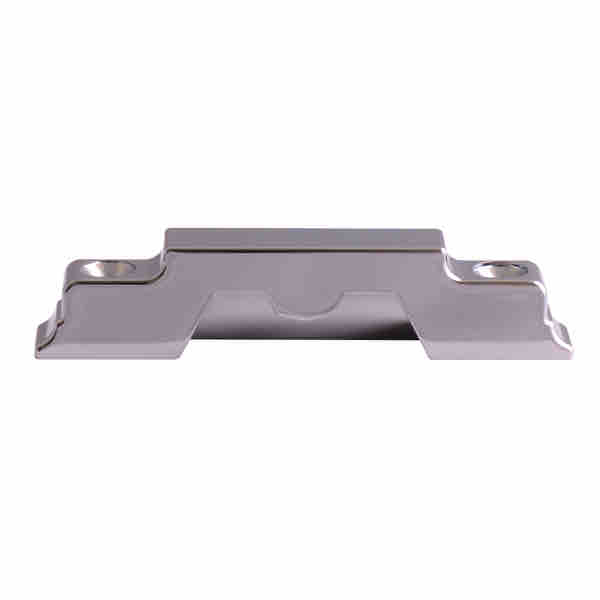

Trickle Vent

We offer two different vent solutions to comply with Document F of the building regulations. Both vents are colour-matched to match the aesthetics of our Legacy sash windows. The modular vent will allow for 2000EA per module and the Link Vent comes in two different sizes: 2500EA and 5000EA.

Deep Bottom Rail

Choose a deep bottom rail if you want your box sash windows to look as close to the original timber sash version as possible. The fully mechanical deep bottom rail convincingly mimics the bottom sash of timber windows from the Victorian era and looks great with run-through sash horns.

Weatherbar

The sash window boasts an optional ovolo shaped weather bar, which is the latest of our heritage design features, developed to create an authentic sash window appearance.

Slide & Tilt Facility

Both the top and bottom sashes can slide up and down for ventilation. Our Legacy sash windows feature an easy clean tilt facility allowing you to clean the external side of your windows from inside the home. Please note, on windows with a woodgrain finish external and smooth finish internal we are not able to offer top sash tilt facility

Integrated Cill

The integrated cill on sash windows combines aesthetic charm with functional benefits. It seamlessly blends with the bottom section of the window, enhancing its visual appeal while also providing protection against moisture damage by deflecting water away from the frame. We offer two different sizes; 150mm for windows installed on an existing cill and 210mm for installations where a projecting cill is required.

Colour Options

Smooth White

Smooth White

External

External

White Grain

White Grain

External

External

White Grain

Smooth White

Cream Grain

Cream Grain

Cream Grain

Smooth White

Grey Grain

Grey Grain

Internal

Internal

Grey Grain

White Grain

Grey Grain

Smooth White

Agate Grey

Agate Grey*

Internal

Internal

Agate Grey

White Grain*

Agate Grey

Smooth White*

Chartwell Green

Chartwell Green*

Chartwell Green

Smooth White*

Black Ash

Black Ash*

Black Ash

Smooth White*

External

External

Irish Oak

Smooth White*

External

External

Golden Oak

Smooth White*

External

External

Rosewood

Smooth White*

Basalt Grey

RAL 7012

Pebble

RAL 7032

Beige

RAL 1001

Stone

RAL 7030

Oyster White

RAL 1013

Papyrus

RALA 9018

Pale Green

RAL 6021

Reed Green

RAL 6013

Hardware Options

The Legacy uPVC sliding sash windows we supply are equipped with a whole range of different hardware. The hardware we use has been carefully selected based on aesthetics, robustness, and ease of use. Our heritage hardware maintains the authentic period charm that makes these windows a great timber replica. Options also include travel restrictors. Finishes may vary by hardware.

Classic Knob

Heritage Knob

Classic Cam Lock

Heritage Lock

Bow handle

Locking Keep

Lift Hook

Pole Eye

Travel Restrictors

White

Satin Silver

Brushed Chrome

Gold

Chrome

Bronze

Black

Antique Black

White

Satin Silver

Brushed Chrome

Gold

Chrome

Bronze

Black

Antique Black

Black

White

Brushed Chrome

Gold

Chrome

Antique Black

Satin Silver

Bronze

White

Brushed Chrome

Satin Silver

Gold

Chrome

Bronze

Black

Antique Black

White

Satin Silver

Brushed Chrome

Gold

Chrome

Bronze

Black

Antique Black

White

Satin Silver

Brushed Chrome

Gold

Chrome

Bronze

Black

Antique Black

Bronze

White

Satin Silver

Brushed Chrome

Gold

Chrome

Black

Antique Black

White

Satin Silver

Brushed Chrome

Gold

Chrome

Bronze

Black

Antique Black

White

Brushed Chrome

Gold

Chrome

Matt Black

Looking for a new supplier of Sliding Sash Windows?

Quote & Order Online 24/7

Creative Marketing Resources

Exclusive Trade Prices

Glazing Options

Double Glazing

Our sash windows come with efficient 24mm double glazing as standard. Double glazing consists of two panes of glass separated by a spacer filled with insulating argon gas. This composition significantly reduces heat transfer, keeping interiors warmer in winter and cooler in summer. Double glazing on uPVC sash windows offers a winning combination of energy efficiency, comfort, security, and aesthetic appeal, making it an excellent choice for both new builds and existing properties.

All our sash windows feature Low E glass, which helps to control the transfer of heat through the glass, keeping interiors cooler in summer and warmer in winter.

Spacer Bars

Spacer bars are positioned around the perimeter of the glass panes to provide structural support to the unit and to ensure that the space between the glass panes

remains consistent. We offer 3 different bar finishes.

Preview finishes

Laminated Glass

You have the option to upgrade your traditional sash windows with laminated glass for enhanced safety while preserving the aesthetic charm of classic Victorian window features. One of the most notable advantages of laminated glass is its safety features. In the event of breakage, the interlayer holds the glass fragments together, preventing them from shattering into sharp pieces.

Obscure Glass

Perfect for privacy-focused areas like bathrooms, we offer obscure glass options – the most popular being Satin glass, also known as frosted glass. It features a smooth, matt finish that lets in natural light while blocking the view from outside.

Venetian Integral Blinds

Venetian integral blinds offer a blend of style and practicality for sash windows. Integrated seamlessly within the double-glazed unit of the window, these blinds provide numerous benefits for homeowners seeking privacy, light control, and energy efficiency. We offer 3 different blind colours for 24mm double glazed units.

| Name | Solar Reflection | Light Reflection | Solar Absorbtion | |

|---|---|---|---|---|

S102 White |

Solar Reflection: 70% |

Light Reflection: 78% |

Solar Absorbtion: 30% |

|

S149 Cream |

Solar Reflection: 68% |

Light Reflection: 75% |

Solar Absorbtion: 32% |

|

S157 Silver |

Solar Reflection: 43% |

Light Reflection: 44% |

Solar Absorbtion: 57% |

| Performance | Value |

|---|---|

| Best U-Value (Double Glazing) | 1.2 W/m²K |

| Best Energy Rating | A |

| Air Tightness (Pa) | Class 4 |

| Water Tightness (Pa) | Class 6A |

| Wind Load (Pa) | Class 3A |

| PAS 24 Security Upgrade | Yes |

| Min Sizes | W: 375mm | H: 800mm |

| Max Sizes | W: 1500mm | H: 2400mm |

Weatherproofing

Our Legacy uPVC sash windows are built to last and to resist the ever-changing conditions the British weather throws at them, all without losing their immaculate appearance. Our sash windows have successfully been tested against wind speeds of up to 120mph to achieve a 1200 rating, while for water tightness it withstood being sprayed with eight litres of water per minute for 40 minutes with zero leakage, earning it a higher-level Class 6A classification.

Thermal Efficiency

The frames and sashes are multi chambered and use the power of specialised argon gas to help trap heat between the panes. Our modern double glazed sash windows can make an excellent timber replacement as they achieve an energy rating of ‘A’ and u-value of 1.2 W/m2K. A sash window with a U-value of 1.2 demonstrates excellent thermal performance, indicating minimal heat loss and efficient insulation properties.

Security

Our double-glazed sash windows deliver the most advanced levels of security without adding complex operations. They are practical and come with all the safety features a homeowner would need. Customers have the option to take advantage of a comprehensive high security PAS 24 package, which meets the latest requirements for new builds. As part of the security upgrade, our sash windows will be equipped with reinforced tilt latched, top security blocks as well as 2 x high security locks and keeps.

Manufacturing Guarantee

With all Quickslide uPVC sash windows, there is a manufacturing guarantee of up to ten years as standard. You can market our uPVC sash windows by providing reassurance to the homeowner. By becoming a trade partner of Quickslide, you can install products that offer complete peace of mind and protected investment. You can provide the best.

This guarantee serves as a testament to our confidence in the durability, reliability, and long-term performance of our sash windows.

Security Options

PAS24 Upgrade

Reinforced Metal Tilt Arms

Top Sash Security Bolts

2x High Security Locks & Keeps

Reinforced Metal Tilt Latches

Conservation & Planning

Conservation Checklist

It’s important you understand specific regulations set forth by your local conservation authority.

Choose sash windows features such as astragal bars and a realistic timber effect that are historically accurate.

Be sure to maintain the original proportions of the windows. We offer two different bottom and midrail sizes.

Provide comprehensive documentation incl. section drawings, specifications, and wood effect swatches.

That’s us! Our knowledge and skills can help ensure that the project meets conservation standards. Quickslide’s sash windows were recently approved for installation in a Grade II listed property in West Yorkshire; read the full case study to discover how we made it happen.

Downloads

FAQs

View All FAQsCan I Replace Existing Timber Windows In a Conservation Area With uPVC Sash Windows?

If you are looking for a sash window replacement that maintains that authentic look while improving thermal performance, choose Quickslide! You can install our products in a conservation area. However, this works on a project by project basis as each area is different.

We can advise on enquiry as to the customisation options that would provide the greatest chance of approval. Our team are here to help!

How Do You Install uPVC Sash Windows?

We always aim to make life easier for trade partners and homeowners alike, so we’ve put all our handy installation guides in one place on our website! For our uPVC sash windows, check out this article for a detailed, step-by-step guide. If you’ve still got questions, get in touch with our team, and they’ll be happy to advise wherever possible.

If you’re a homeowner, we recommend finding your local installer to ensure you receive a professional fit for your sash window replacement.

How Much Do uPVC Sash Windows Cost?

The sash window cost can vary depending on the size, style, and any optional features and accessories you choose. However, our recommended retail price for uPVC sash windows start from £396 including VAT, making them an affordable option for homeowners looking to add heritage charm with modern performance. Every window is made to measure, so for an accurate price based on your specific requirements, you can use our online window designer or get in touch with our team for a quote.

What Are uPVC Sash Windows?

uPVC sash windows, also known as vertical sliders or vertical sliding windows, are a traditional style of window still proving to be popular today. uPVC sash windows feature two sashes that slide up and down, as well as tilt and slide. Our Legacy model offers nothing but the highest quality, as well as meeting our high standards for aesthetics, performance, and security.

There are many aesthetics that fall under the “sash” style. These include Victorian, Edwardian, and Georgian. Quickslide can provide each of these styles and can even provide curved variations, which you can find here.

Are Sash Windows Energy Efficient?

Quickslide double glazing is filled with argon gas to provide optimal thermal efficiency. Homes can stay warm and stylish when you choose Quickslide.

How Secure Are Sash Windows?

Quickslides come with modern locking mechanisms and are made with highly durable materials that can resist warping and sudden blows. We also offer a PAS 24 upgrade package for those serious about security.

Double glazing is more robust than singular glazed panes due to the thicker doubled up panes, making them harder to break through while also being more energy efficient.

What Areas Can You Cover?

We cover a broad selection of areas across the UK for all of our products, including Alresford, Birmingham, Bristol, Canterbury, Dundee, Eastleigh, Fareham, Glasgow, London, Manchester, Northampton, Southampton, Winchester, Wolverhampton, York, and many more. To see more of the areas we cover, please visit our delivery page.

How Do I Fit The Bottom Sash On uPVC Sliding Sash Windows?

Our video on how to fit the bottom sash on uPVC sliding sash windows can provide a step-by-step guide. For further help, contact a Quickslide professional via our contact form.

Can You Put Sash Windows In Any House?

Yes, you can install sash windows in most UK homes, whether they are heritage sash, traditional box, or bespoke sash designs. However, some homes may be better suited for other window styles. If your home is listed or located in a conservation area, always check for restrictions. Modern uPVC sash windows come in both classic and modern styles, offering great versatility.

Do I Need Planning Permission To Replace Sash Windows?

In most UK homes, you won’t need planning permission to replace sash windows if the new ones match the style and material of the existing windows. But if your home is listed or in a conservation area, you will probably need permission. It’s always a good idea to check with your local council just to be sure.

Quickslide Trade Stockist Programme

Get access to our online trade price lists, marketing support, order forms and much more by registering as a Trade Stockist today!

Register Now

Find an Installer

Find your nearest installer from our network of stockists. Enter your postcode to get started!

Find an Installer